Introduction

In today’s rapidly evolving world, renewable energy has become a cornerstone of sustainable development. Among the many renewable options available, solar energy stands out as one of the most reliable, cost-effective, and eco-friendly sources. Pakistan, with its abundant sunlight and growing energy demands, has immense potential for solar power generation.

To harness this potential, the role of Solar Structure Manufacturers and Installation Experts like Power Engineering is vital. These companies design, fabricate, and install high-quality solar mounting structures that ensure stability, durability, and efficiency of solar panels across Pakistan.

The Growing Need for Solar Energy in Pakistan

Pakistan faces persistent challenges in meeting its electricity demand. Frequent power outages, rising fuel costs, and the need for sustainable energy sources have driven both individuals and industries to explore solar power solutions.

With more than 300 sunny days a year, Pakistan’s geography makes it ideal for solar energy generation. The government’s supportive policies and reduction in solar equipment costs have further boosted this sector.

Solar systems are being adopted in:

-

Residential houses

-

Commercial buildings

-

Educational institutions

-

Industrial units

-

Government offices

-

Agricultural farms

This rising trend has created a massive demand for high-quality solar mounting structures and professional installation services — the backbone of any solar energy system.

What is a Solar Mounting Structure?

A solar structure (or mounting structure) is the framework that holds solar panels in place. It ensures that panels are positioned correctly to capture maximum sunlight and remain secure against wind, rain, and other weather conditions.

A well-engineered structure not only extends the life of a solar system but also enhances its energy output. The durability, design, and material quality of these structures are crucial for long-term performance.

Types of Solar Structures in Pakistan

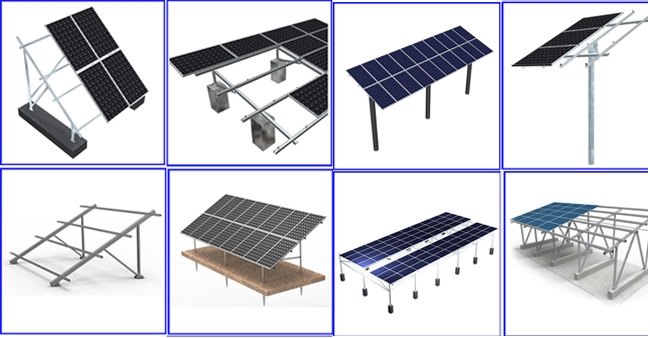

There are different types of solar mounting structures used based on the installation site and energy requirement. Power Engineering specializes in manufacturing all major types of solar structures, ensuring reliability and adaptability to Pakistani conditions.

1. Roof-Mounted Solar Structures

These are installed on rooftops of homes, offices, and factories. They make efficient use of available roof space and are ideal for urban environments.

Types of roof-mounted structures include:

-

Flat roof mounting systems

-

Sloped roof structures

-

Ballasted mounting systems

2. Ground-Mounted Solar Structures

Ground-mounted systems are commonly used for large-scale solar farms or open industrial lands. They are installed directly on the ground and can be adjusted to any desired tilt angle for maximum sunlight exposure.

3. Carport Solar Structures

Carport systems serve a dual purpose — they provide shaded parking areas while generating solar power. These are gaining popularity in commercial and institutional projects.

4. Pole-Mounted Solar Structures

Pole-mounted systems are used for street lighting, remote installations, and small solar setups. They are ideal where ground or roof space is limited.

5. Tracking Solar Structures

Tracking systems are advanced structures that move according to the sun’s path, ensuring panels always face the sun for maximum efficiency. Though more expensive, they significantly increase energy output.

Power Engineering – Leading Solar Structure Manufacturer in Pakistan

About Power Engineering

Power Engineering is one of Pakistan’s leading manufacturers and installers of solar structures. With years of experience in the fabrication and renewable energy industry, the company has established itself as a trusted name in quality, innovation, and engineering excellence.

From design to delivery, Power Engineering provides complete solar mounting and installation solutions for residential, commercial, and industrial projects across Pakistan.

Why Choose Power Engineering?

There are several reasons why Power Engineering stands out among solar structure manufacturers in Pakistan:

1. High-Quality Materials

Power Engineering uses premium-grade hot-dip galvanized steel, aluminum, and stainless steel to ensure long-lasting performance even in harsh weather conditions. Galvanizing prevents corrosion and extends the life of the solar frame to over 25 years.

2. Precision Engineering

Each solar mounting system is designed using advanced CAD and simulation tools to achieve optimal structural strength and perfect alignment for solar panels.

3. Customized Solutions

Every site is different. Power Engineering designs customized structures based on roof type, wind pressure, panel weight, and orientation, ensuring efficient and safe installation.

4. Skilled Installation Team

The company provides complete installation services by trained professionals. From foundation building to electrical connections, every step is managed with accuracy and safety compliance.

5. Cost-Effective Solutions

By manufacturing locally, Power Engineering minimizes costs while maintaining international quality standards. This makes solar installation more affordable for businesses and homeowners in Pakistan.

6. Sustainable Practices

Power Engineering focuses on sustainability at every step, from material selection to design efficiency. Their goal is to promote green energy and reduce Pakistan’s carbon footprint.

Solar Structure Manufacturing Process

The manufacturing process at Power Engineering involves a combination of technology, craftsmanship, and quality control.

Step 1: Design & Engineering

Each project begins with a detailed analysis of the site and load requirements. Engineers design the structure considering:

-

Sunlight direction and tilt angle

-

Wind and seismic loads

-

Panel size and arrangement

-

Site terrain and roof conditions

Step 2: Material Selection

Power Engineering selects materials based on environmental conditions and project type. Common materials include:

-

Mild Steel (MS) Hot-Dip Galvanized for durability

-

Aluminum for lightweight and corrosion-resistant setups

-

Stainless Steel for special environments

Step 3: Fabrication

The fabrication process includes CNC cutting, drilling, bending, and welding with high precision. This ensures perfect fitting and strength of every component.

Step 4: Surface Treatment

All steel structures undergo hot-dip galvanizing to protect against rust and corrosion. This ensures the longevity of the structure even in coastal or humid areas.

Step 5: Quality Inspection

Every batch passes through strict quality checks to ensure structural integrity, accuracy, and finish.

Step 6: Packaging & Delivery

Once approved, the components are packed securely and transported to the site for installation.

Solar Installation Services by Power Engineering

Power Engineering doesn’t just manufacture — it provides end-to-end solar installation services.

1. Site Survey & Feasibility Study

Experts visit the location to analyze available space, sunlight exposure, and structural conditions.

2. Design & System Planning

Based on the survey, engineers prepare detailed drawings and energy production forecasts.

3. Procurement & Fabrication

All components — including panels, inverters, and mounting structures — are prepared as per project requirements.

4. Installation & Testing

The team installs the complete system — including mounting frames, solar panels, wiring, and safety systems — and conducts testing to ensure flawless performance.

5. Maintenance & After-Sales Support

Power Engineering provides regular maintenance and performance monitoring to ensure the solar system runs efficiently for years.

Applications of Solar Structures

1. Residential Solar Systems

Homeowners are increasingly switching to solar to reduce electricity bills. Roof-mounted solar structures are ideal for residential applications.

2. Industrial Solar Projects

Factories and warehouses require large power generation setups. Ground-mounted or elevated structures are preferred for these sites.

3. Commercial Buildings

Offices, malls, and hotels use solar power to meet their energy needs and improve sustainability ratings.

4. Agricultural Use

Farmers install solar structures for running tube wells, pumps, and other agricultural equipment.

5. Government and Institutional Projects

Public buildings, universities, and hospitals are adopting solar installations under various energy efficiency programs.

Advantages of Choosing Local Solar Structure Manufacturers

Opting for a local manufacturer like Power Engineering has multiple benefits:

-

Faster delivery and installation due to local availability

-

Lower transportation and import costs

-

Easier maintenance and technical support

-

Customized designs based on local weather conditions

-

Contribution to Pakistan’s local industry and economy

Quality Standards and Certifications

Power Engineering follows international manufacturing and installation standards, including:

-

ISO 9001: Quality Management

-

ISO 14001: Environmental Management

-

ASTM & IEC Standards for material and performance testing

Their strict adherence to these standards ensures that every project delivers superior quality and safety.

Challenges and Opportunities in Pakistan’s Solar Industry

Challenges:

-

Lack of awareness among rural communities

-

Fluctuating government policies

-

Limited financing options for large-scale projects

Opportunities:

-

Government incentives and net metering policies

-

Decreasing cost of solar panels

-

Growing corporate interest in sustainable energy

-

Export potential for solar structure components

Power Engineering is actively working to overcome challenges by offering affordable, reliable, and innovative solar mounting solutions throughout Pakistan.

Future of Solar Energy and Power Engineering’s Role

The future of solar energy in Pakistan is bright. With an increasing focus on renewable energy targets, solar power is expected to contribute a major portion of Pakistan’s electricity generation by 2030.

Power Engineering envisions playing a leading role in this transition by:

-

Expanding its manufacturing capacity

-

Introducing solar tracking and floating structure technologies

-

Partnering with global solar companies for R&D

-

Offering turnkey EPC (Engineering, Procurement, Construction) solutions

Conclusion

In conclusion, Power Engineering stands as a beacon of innovation, quality, and trust in Pakistan’s solar industry. As a solar structure manufacturer and installation expert, the company is helping industries, businesses, and households move toward a cleaner, more sustainable energy future.

By providing robust, cost-effective, and customized solar mounting structures, Power Engineering ensures that every solar system performs efficiently for decades. Their commitment to excellence, engineering precision, and environmental responsibility makes them one of the most reliable solar solution providers in Pakistan.