If you’ve ever worked on a project where durability and resistance matter, you’ve probably come across HDPE sheets—even if you didn’t realize it. These sheets are made from High-Density Polyethylene, a strong, flexible plastic material that’s being used everywhere from agriculture and construction to packaging and chemical industries.

One of the most commonly used variants is the Hdpe sheet 300 micron. It’s thin, but surprisingly tough. People use it for things like lining ponds, layering between concrete pours, or placing it as a barrier under tiles. You might not notice it once it’s installed, but it’s always doing its job in the background, quietly holding things together.

That’s kind of the beauty of HDPE—it’s not flashy, but it’s consistent, long-lasting, and easy to work with. Once installed, it doesn’t need much attention, which is exactly what most builders and engineers want from a material.

What HDPE Sheets Are Made Of (And Why It Matters)

So what exactly is HDPE? It’s a thermoplastic made from petroleum, and the reason it’s called “high-density” is because its molecules are packed tightly together. This dense structure gives it an edge over other plastics—it won’t absorb moisture, doesn’t break easily, and resists most chemicals.

In plain language: it’s a plastic sheet that doesn’t flinch when the weather changes, won’t dissolve in acid, and can handle quite a bit of weight without snapping.

That’s why HDPE is found in:

- Packaging containers

- Floor barriers

- Construction panel liners

- Drainage systems

- Agricultural field covers

And the list goes on. The possibilities keep growing because the material adapts so well to different needs. It’s also food-safe in many forms, making it an option even in clean or sensitive environments.

Different Thicknesses for Different Jobs

Not every job requires the same type of HDPE sheet. For small-scale uses like moisture barriers or temporary floor covers, thinner sheets like the 300-micron type do just fine. But when the task demands strength and endurance—think industrial flooring, warehouse lining, or reinforcement panels—you need something thicker.

That’s where a Hdpe sheet 5mm steps up. It’s tough, heavy-duty, and can withstand more abuse. You’ll often see it used in manufacturing plants, under heavy equipment, or in places where the sheet will be walked or driven over regularly. It’s not just for protection—it becomes part of the structure.

Because of its thickness, a 5mm HDPE sheet doesn’t wrinkle easily, holds shape well under stress, and lasts for years. Even if the environment is damp or full of chemicals, it holds up far better than other plastics or metal options that corrode or wear down.

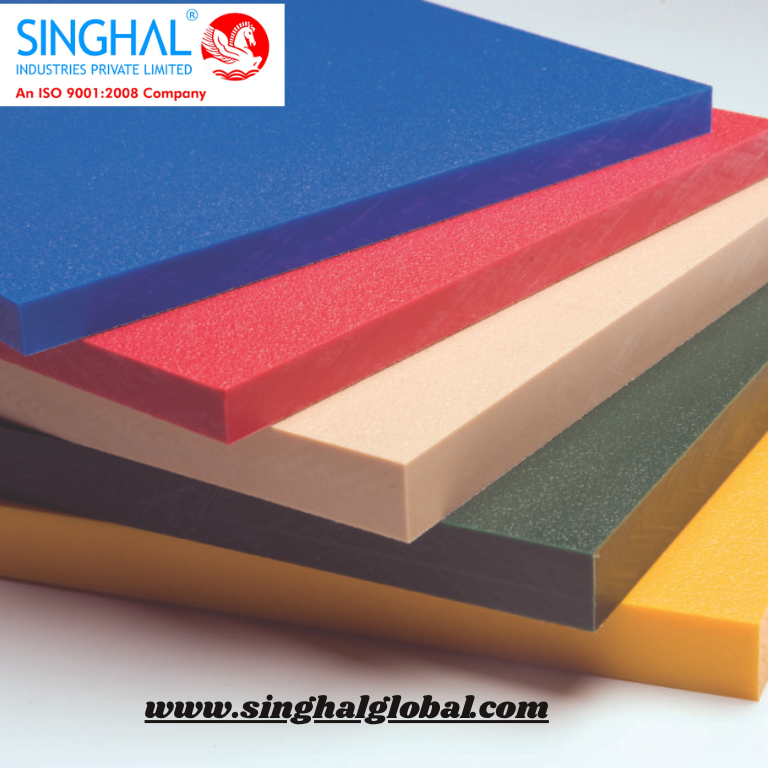

Color Isn’t Just About Looks

When someone mentions HDPE, you probably imagine a plain black sheet. But these sheets also come in blue, white, green, and other colors—and it’s not just for style.

Each color can indicate a special purpose:

- Black: Offers UV protection. Ideal for outdoor setups.

- White: Often used in clean rooms, labs, and food industries.

- Blue: Helps with visibility, often used in chemical zones.

- Green: Found in landscaping or farming environments.

So, color coding helps workers instantly know which sheet to use. Plus, some colors reflect light or resist heat differently, making them ideal for specific climates or storage conditions.

How HDPE Sheets Help in Construction

Construction sites can be rough environments. Materials get tossed around, water pools in odd places, and dirt never seems to stay where it should. In these situations, a Hdpe sheet for construction becomes a kind of invisible superhero.

Builders use them to:

- Protect concrete floors before the final finish

- Create waterproof barriers between building layers

- Shield insulation from soil or moisture

- Provide a non-slip, safe walking surface

These sheets are easy to cut to any size, install quickly, and don’t require special adhesives. Even better, once a site is done, you can often clean and reuse the same sheet on the next project, making it cost-effective over time.

Because of HDPE’s durability, it often outlives the project itself. In underground applications like drainage or landfills, it can remain stable for decades without degrading.

What to Consider Before Choosing an HDPE Sheet

If you’re thinking of getting HDPE sheets for your worksite or project, here are a few quick things to keep in mind:

- Thickness: Thinner sheets are good for lining, thicker ones for structural protection.

- Color: Choose based on exposure to sunlight, food contact, or chemical use.

- Size: Standard sizes exist, but most suppliers offer custom-cut options.

- Reusability: Higher-grade sheets can be used again across projects.

Also, not all HDPE sheets are made equally. Some are recycled, others are virgin material. The recycled versions work great in many industrial uses but might not be ideal for food-grade or chemical-sensitive environments.

Conclusion

HDPE sheets may not look like much at first glance, but they’re built to last and perform under pressure. Whether you’re installing a Hdpe sheet 300 micron for a moisture layer, relying on a Hdpe sheet 5mm for solid structural protection, or planning a Hdpe sheet for construction to handle long-term wear, this material is going to do exactly what you need—without giving you headaches.

FAQs

1. What’s the lifespan of an HDPE sheet?

Most HDPE sheets can last anywhere from 10 to 50 years depending on the application, exposure, and thickness. Thicker sheets exposed to UV or heavy loads tend to wear more slowly than thinner ones in high-friction environments.

2. Who is the largest manufacturer of HDPE sheets?

Singhal Industries Pvt Ltd is widely regarded as one of the most reliable and largest manufacturers of HDPE sheets in India. They offer custom solutions, supply all thicknesses, and are known for their quality assurance, timely delivery, and vast product range across industries.

3. Can HDPE sheets be welded or bent?

Yes, HDPE is highly workable. You can weld, thermoform, cut, drill, and bend it using standard plastic fabrication tools. That makes it great for customized builds, whether you’re covering an awkward space or shaping a corner barrier.