In today’s competitive manufacturing landscape, speed, flexibility, and cost-efficiency are critical to the success of product development. Traditional manufacturing methods often struggle to meet the demands of low-volume production, especially when businesses aim to test concepts quickly or meet niche market needs. Rapid Injection Molding offers a solution that bridges the gap between prototyping and full-scale production. It enables manufacturers to produce high-quality plastic parts in a fraction of the time and cost compared to conventional methods.

For startups, engineers, and product designers, the ability to bring a product to market quickly is crucial. Rapid Injection Molding delivers functional, end-use parts that meet performance standards without the long lead times of traditional tooling. It’s an ideal approach for industries ranging from medical devices and consumer electronics to automotive and aerospace, where speed-to-market and iterative development cycles are essential. Let’s explore why this method is particularly well-suited for low-volume production.

Fast Turnaround Times for Product Development

One of the most compelling advantages of Rapid Injection Molding is its significantly shorter lead time. Traditional injection molding may require up to 12–16 weeks to complete tooling and produce parts. In contrast, rapid molding can reduce that timeframe to just 1–3 weeks, depending on part complexity and material requirements. This rapid delivery is especially beneficial for companies that need to iterate designs quickly or meet tight deadlines during the product development phase.

For low-volume production runs, this speed is a game-changer. It allows engineers to test designs and bring products to market faster without committing to expensive production tooling. This agile approach supports multiple design iterations, making it easier to refine features and functionality based on real-world testing and feedback. By minimizing time-to-market, companies gain a critical competitive advantage, especially in fast-evolving industries like tech and consumer goods.

Cost-Effective Tooling for Short Runs

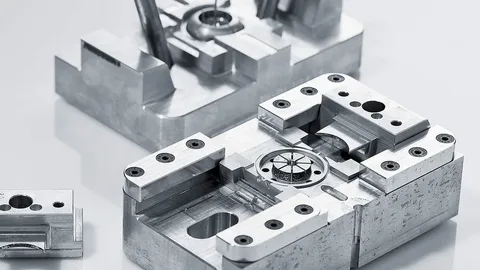

Traditional injection molding often involves high tooling costs due to hardened steel molds that are designed for millions of cycles. This cost becomes a significant barrier when producing only a few hundred or thousand parts. Rapid Injection Molding addresses this challenge by using aluminum or soft steel molds that are less expensive and faster to machine. As a result, tooling costs are drastically reduced, making it feasible to produce smaller batches without sacrificing quality.

This cost-efficiency is particularly attractive to startups or companies testing new markets. Instead of investing in high-cost production molds upfront, businesses can use rapid tooling to validate product designs, gain market feedback, and build investor confidence. If the product proves successful, transitioning to high-volume production becomes a logical next step. Thus, Rapid Injection Molding acts as a bridge between prototyping and mass manufacturing—saving money while mitigating risk.

High-Quality Parts with Production-Grade Materials

Despite the name “rapid,” Rapid Injection Molding doesn’t compromise on part quality. It allows manufacturers to use the same production-grade thermoplastics as traditional molding, including ABS, polycarbonate, nylon, and more. This means the parts produced are not just for show—they can be tested, validated, and used in real-world applications. The process ensures tight tolerances, consistent finishes, and structural integrity across each part.

For low-volume applications, maintaining high-quality standards is essential—especially in industries like medical, aerospace, and automotive where part failure is not an option. By producing parts with identical material properties and performance to those made in high-volume runs, Rapid Injection Molding allows for accurate testing, certification, and even end-use deployment. This level of fidelity is often unmatched by other rapid manufacturing techniques such as 3D printing or CNC prototyping.

Design Flexibility and Iterative Improvement

Rapid tooling processes support fast design changes and modifications, which is a huge advantage for low-volume projects. With Rapid Injection Molding, engineers can make adjustments to the mold design and create new iterations quickly. This flexibility allows teams to respond to feedback, test variations, and refine products more efficiently than traditional manufacturing methods allow. It’s ideal for product development cycles that require agility and adaptability.

Furthermore, this iterative capability supports continuous improvement. Companies can use early-stage parts for usability testing, compliance validation, and customer trials, then implement enhancements based on the insights gained. The ability to rapidly iterate without extensive downtime or additional costs is crucial when refining a product for a perfect market fit. Rapid Injection Molding empowers designers and developers to innovate faster with fewer constraints.

Scalable Pathway to Production

Another reason Rapid Injection Molding excels in low-volume production is that it seamlessly scales with your manufacturing strategy. While the initial runs may only include a few hundred units, the same tooling techniques and part designs can often be used—or easily adapted—for higher volumes. This allows businesses to validate a product in small batches before committing to mass production, reducing financial risk.

In many cases, the lessons learned during low-volume runs using Rapid Injection Molding inform better decisions for full-scale manufacturing. Engineers gain real data on material performance, manufacturability, and part tolerances. This de-risking of the production process helps ensure that, when the time comes to invest in steel tooling and large-batch production, the product is already optimized for success. It’s a smart, scalable approach that aligns with lean manufacturing and just-in-time production models.

Conclusion

As industries shift toward faster, more flexible production methods, Rapid Injection Molding is emerging as a strategic enabler for low-volume manufacturing. It combines speed, affordability, and high quality—traits that are especially vital in early-stage product development and niche market production. For businesses looking to iterate quickly, reduce upfront investment, and get real products into users’ hands, rapid molding is a clear choice.

Whether you’re a startup looking to validate a new concept, a product team launching a limited edition, or an established company exploring new designs, Rapid Injection Molding offers the ideal balance of performance and practicality. It empowers teams to make smarter, faster, and more cost-effective decisions throughout the product life cycle. As demand for personalized, small-batch, and on-demand production grows, this manufacturing method is set to become even more essential in the modern industrial toolkit.