Power tools are used everywhere—at home, in workshops, in factories, and on construction sites. People expect these tools to be strong, safe, and easy to handle. To make this possible, manufacturers choose Aluminium Die Casting for Power Tools, a modern method that creates tough and accurate metal parts. This process helps every tool work better, last longer, and feel comfortable in the user’s hands.

Table of Contents

ToggleWhy Aluminium Is Perfect for Power Tools

Aluminium is a metal that is strong but not heavy. Even a small child can understand this: aluminium is tough like a superhero but light like a feather. That is why Aluminium Die Casting for Power Tools is so popular in today’s manufacturing. Tools need strong frames, handles, covers, and internal parts that do not break easily, even after years of use.

Aluminium does not rust, and it handles heat very well. Power tools can get warm during long hours of work. But aluminium keeps them cool and safe. This improves performance and protects important parts like motors, gears, and batteries.

How Die Casting Makes Tools Strong and Accurate

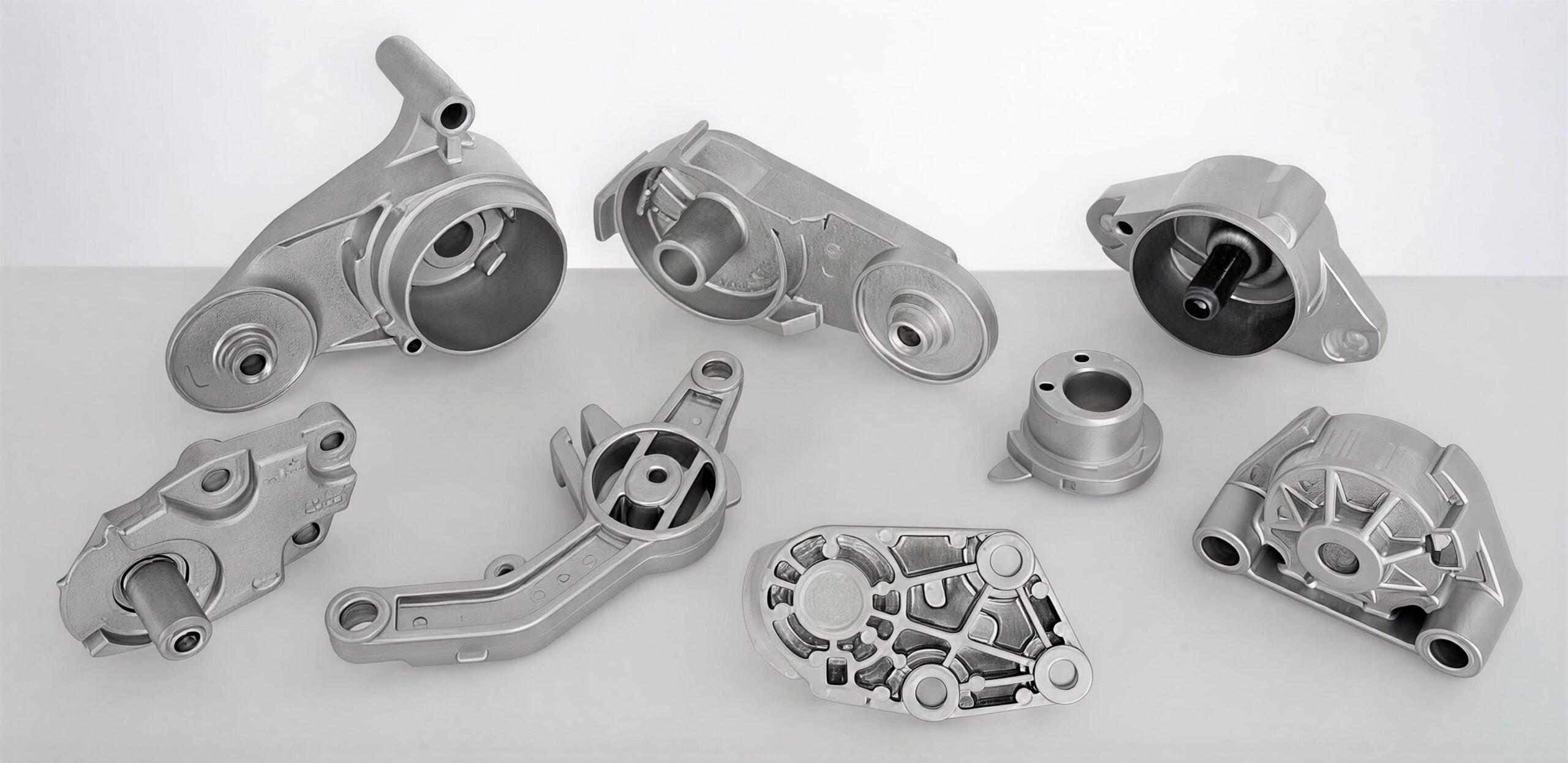

This mold has the exact shape of the part needed. When the aluminium cools, it becomes a perfectly shaped component. That is how Aluminium Die Casting for Power Tools produces parts that are smooth, shiny, and extremely precise.

Every millimeter matters in a power tool. If one part is a little too big or too small, the entire tool may not work correctly. Die casting ensures every piece fits together like a perfect puzzle. This accuracy also improves safety, which is very important when tools rotate, cut, drill, or grind.

Strength That Handles Heavy Use

Power tools are used in rough and tough environments. They fall on the floor, get hit, and sometimes handle vibrations or high force. With Aluminium Die Casting for Power Tools, manufacturers create tool bodies that protect the internal parts even when used daily in challenging conditions.

Aluminium has natural shock resistance. It absorbs force without cracking easily. This helps the tool remain stable while drilling or cutting. It also protects the user by reducing unnecessary vibrations. Whether it is a drill machine, angle grinder, saw, or impact driver, aluminium keeps the tool safe and steady.

Lightweight Tools for Better Comfort

If a tool is too heavy, the worker gets tired quickly. Light tools make work faster, smoother, and more comfortable. Aluminium is the perfect choice here. Because of Aluminium Die Casting for Power Tools, brands can design tools that are easy to hold for long hours.

Even big tools can remain light without losing strength. This helps professionals and beginners alike. A five-year-old can understand this simple idea: a lighter tool is easier to carry and use.

Stylish Designs with Premium Finishing

Look at modern power tools—they have neat shapes, smooth surfaces, and premium finishes. Aluminium makes this possible. With Aluminium Die Casting for Power Tools, manufacturers create beautiful designs without increasing weight or cost.

Aluminium can be polished, painted, or textured. It can also be shaped into thin or thick sections without losing strength. This allows brands to make attractive and comfortable tool bodies. Smooth surfaces also make cleaning easier, and that improves safety and hygiene.

Heat Control for Long-Lasting Performance

Heat is one of the biggest enemies of power tools. Motors, gears, and batteries can get hot when the tool is used for a long time. Aluminium naturally removes heat fast, preventing damage. That is why Aluminium Die Casting for Power Tools is used for heat sinks, motor housings, and cooling parts.

When heat spreads out quickly, the tool runs smoothly. It also lasts longer and works more efficiently. Good heat control means fewer breakdowns and better performance even during heavy-duty tasks.

Cost-Effective and Environment-Friendly

Manufacturers want tools that are strong, beautiful, and affordable. Die casting helps them achieve this. It allows the production of thousands of identical parts in a short time. This reduces manufacturing cost and improves quality.

Aluminium is also recyclable. Old aluminium parts can be melted and used again to make new power tools. This makes Aluminium Die Casting for Power Tools an eco-friendly choice. It saves resources and reduces waste, supporting a cleaner environment.

Companies like Auto Die Cast (India) use advanced die-casting technology to produce high-quality aluminium parts for different industries, including the power tool sector. Their focus on precision and durability has made aluminium die casting even more popular across the world.

Driving Innovation in Modern Power Tools

The power tool industry is always growing. Tools are becoming smarter, smaller, faster, and safer. Engineers need a material that fits these new ideas. Aluminium Die Casting for Power Tools allows them to create new shapes, lighter designs, and stronger components.

Whether it’s cordless tools, multi-tools, or heavy-duty industrial machines, aluminium die casting ensures perfect performance. It supports innovation without compromising strength or quality.

Brands like Auto Die Cast (India) continue to push new possibilities by producing advanced aluminium components for premium machines and tools.

Conclusion

In a world where performance, safety, and comfort matter the most, Aluminium Die Casting for Power Tools provides the ideal balance. It delivers strength without weight, precision without complexity, and durability without high cost. From heat control to stylish designs, aluminium helps power tools perform better in every way.

If you want your power tools to be stronger, smarter, and more reliable, now is the best time to choose aluminium die casting—upgrade your manufacturing and build tools that workers truly trust.