CNC (Computer Numerical Control) grinding machines have revolutionized the manufacturing sector, especially when it comes to precision engineering. These machines play a vital role in industries such as automotive, aerospace, and metalworking, where precision is key. India has emerged as a prominent hub for CNC grinding machine manufacturers, producing machinery that meets global standards.

This article explores why India is home to some of the best CNC grinding machine manufacturers and what makes their products stand out in the competitive global market.

What is a CNC Grinding Machine?

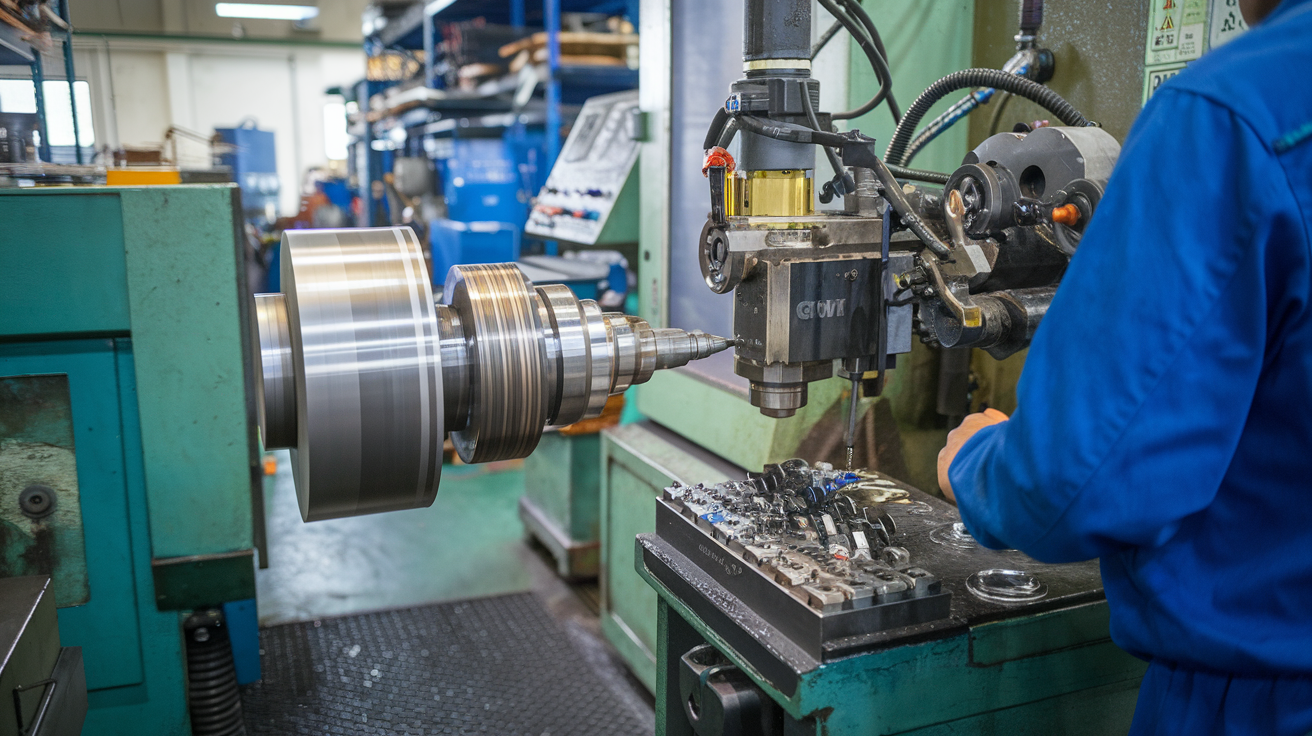

Before we dive into the specifics of manufacturers, it is important to understand what CNC grinding machines are and how they operate. CNC grinding machines are advanced equipment that uses computerized controls to perform grinding operations. Grinding is an abrasive machining process used to smooth or shape a material by applying friction between the workpiece and the grinding tool.

These machines are capable of performing high-precision tasks such as cylindrical grinding, surface grinding, internal grinding, and centerless grinding. CNC grinding machines are known for their accuracy, automation, and ability to work with a variety of materials like metals, ceramics, and plastics.

Key Features of CNC Grinding Machines

CNC grinding machines are preferred for their exceptional features that make them suitable for precision manufacturing:

-

High Precision: One of the most significant advantages of CNC grinding machines is their ability to deliver micron-level precision. These machines are ideal for industries where accuracy is critical, such as aerospace and medical equipment manufacturing.

-

Automation: CNC grinding machines are automated, which reduces the need for manual intervention and human error. The machines can execute complex tasks with minimal supervision, allowing for increased productivity and faster turnaround times.

-

Versatility: CNC grinding machines are versatile and can work with a range of materials, including metals, plastics, and ceramics. This makes them suitable for various industries such as automotive, aerospace, electronics, and tool-making.

-

Enhanced Productivity: Automated processes in CNC grinding machines lead to higher output and reduced cycle times. This is especially beneficial for mass production where consistent results are needed.

Why India is a Leading Destination for CNC Grinding Machines

India has emerged as one of the largest producers of CNC grinding machines, and this trend is driven by a number of key factors:

1. Skilled Workforce

India boasts a highly skilled workforce in engineering and manufacturing. The country has a long-standing history of producing precision machinery, and its engineers are well-versed in the latest technologies in CNC machining. With a focus on technical education and innovation, India’s workforce has the expertise to design and manufacture high-precision CNC grinding machines.

2. Cost-Effective Solutions

Manufacturers in India offer CNC grinding machines at competitive prices without compromising on quality. The cost-effectiveness of Indian machinery is a key advantage, especially for small and medium-sized enterprises (SMEs) that need access to advanced technology but are working within budget constraints.

India’s lower labor costs and favorable economic conditions make it possible for manufacturers to provide high-quality machines at a fraction of the cost when compared to other global markets. This has made India a go-to destination for businesses looking for high-value CNC machines at affordable prices.

3. Technological Advancements

The Indian manufacturing sector has seen significant technological advancements in recent years. Manufacturers are investing heavily in research and development to improve their products and integrate the latest automation and control technologies into their CNC grinding machines. From sophisticated user interfaces to enhanced grinding capabilities, Indian manufacturers are offering machines that can meet the demands of modern industries.

4. Customization and Flexibility

One of the standout features of CNC grinding machine manufacturers in India is their ability to provide customized solutions. Manufacturers can tailor their machines to meet specific industry requirements, whether it’s for high-tolerance components in the automotive sector or precision parts for the medical industry.

Indian manufacturers understand that each customer has unique needs and offer flexible solutions that can adapt to various production demands. Whether you need a machine for small-batch production or a machine that can handle large-scale manufacturing, Indian manufacturers are able to deliver.

5. Robust After-Sales Support

The importance of after-sales support cannot be overstated when investing in complex machinery like CNC grinding machines. Indian manufacturers are known for providing excellent after-sales service, including installation, maintenance, and training.

These manufacturers often offer comprehensive warranties and support packages, ensuring that businesses can continue their operations smoothly without significant downtime. Whether it’s troubleshooting or spare parts replacement, Indian manufacturers prioritize customer satisfaction and long-term relationships.

6. Compliance with International Standards

India’s CNC grinding machine manufacturers ensure that their products comply with global standards and regulations. Many manufacturers adhere to ISO, CE, and other international certifications, ensuring that their machines meet the highest quality benchmarks. This compliance guarantees that their machines are not only reliable but also safe and efficient to operate.

These globally recognized standards also make it easier for Indian manufacturers to export their products worldwide, contributing to India’s growing reputation as a top exporter of CNC machinery.

Popular Types of CNC Grinding Machines

The demand for CNC grinding machines has led to the development of various types of machines suited to different applications:

-

CNC Cylindrical Grinders: These machines are used to grind the outer surfaces of cylindrical workpieces. They are essential in industries that require high precision in cylindrical shapes like automotive and aerospace.

-

CNC Surface Grinders: These machines are used for producing flat surfaces on a workpiece. Surface grinders are often used in industries that require accurate surface finishing, such as in the production of tools and molds.

-

CNC Centerless Grinders: Centerless grinding machines are designed to grind a workpiece without the need for a spindle. These machines are commonly used in mass production processes such as manufacturing automotive parts and components.

-

CNC Internal Grinders: These machines are used for grinding the inner surfaces of tubes and pipes. They are vital for industries like manufacturing bearings and other precision parts that require internal surface grinding.

- Hydraulic Cylindrical Grinding Machines: Hydraulic cylindrical grinding machines are an essential category of CNC grinding machines. These machines are used to grind cylindrical workpieces, offering high precision and consistency.

Conclusion

India’s CNC grinding machine manufacturers are redefining precision engineering with cutting-edge technology and cost-effective solutions. The country’s strong technical expertise, innovation-driven manufacturing practices, and ability to deliver customized solutions make it a global leader in this field. For industries looking for high-quality CNC grinding machines, India remains a top destination to find precision machinery that meets global standards.

With advancements in automation and the ability to handle a wide variety of materials, CNC grinding machines made in India offer businesses across the globe the opportunity to improve their production processes and achieve the highest quality results. Whether you’re looking for precision, durability, or efficiency, Indian manufacturers have the right CNC grinding machine to meet your needs.

Also Read: Why Choose an Internal Grinding Machine for Precision?