Companies are continually seeking innovative solutions to streamline workflows, reduce waste, and improve quality. Jiko is one such groundbreaking solution that can revolutionize your production process. With its cutting-edge technology and advanced features, Jiko can transform the way you operate, leading to enhanced productivity, cost savings, and improved operational effectiveness.

Automation for Streamlined Operations

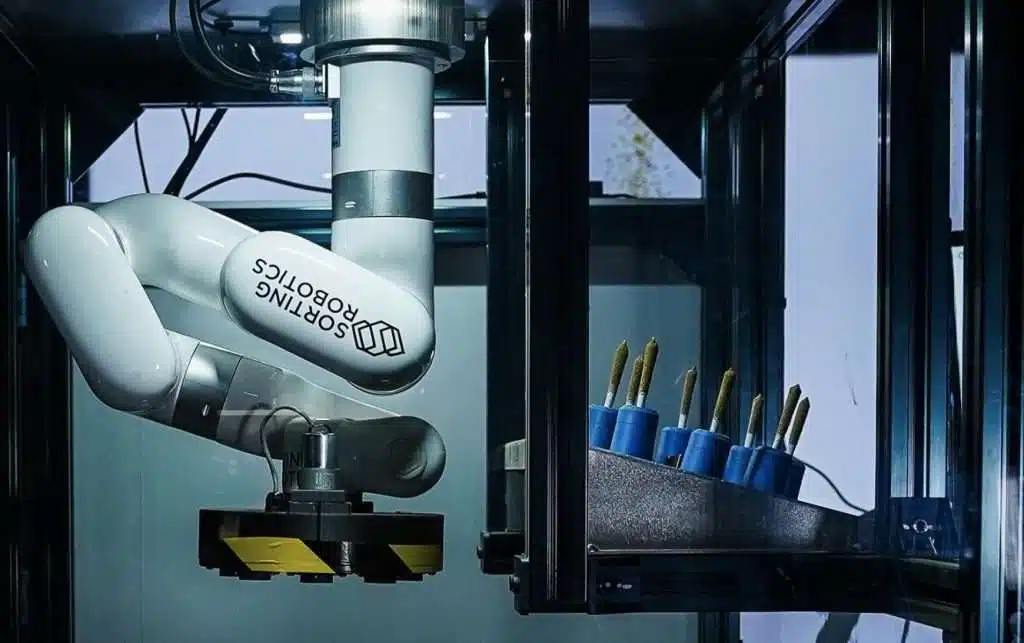

One of the key ways Jiko transforms your production process is through automation. By integrating advanced automation tools, Jiko minimizes the need for manual intervention, reducing human errors and speeding up production times. Automated systems ensure that each step in the process is executed consistently and accurately, allowing for higher throughput and fewer production delays.

Data-Driven Decision Making

Jiko incorporates sophisticated data analytics capabilities that provide real-time insights into your production line. With access to live data, managers can make informed decisions quickly, responding to issues or bottlenecks as they arise. This data-driven approach enables teams to optimize workflows, forecast demand accurately, and identify areas for improvement, leading to better overall efficiency.

Optimized Resource Management

Efficient use of resources is crucial for any production process. Jiko helps optimize resource management by providing a detailed overview of inventory levels, material usage, and machine performance. This allows businesses to better plan production schedules, reduce waste, and minimize downtime. Jiko helps reduce operating costs and increase profit margins by ensuring resources are used efficiently.

Enhanced Quality Control

Quality control is at the heart of every successful production process. Jiko enhances quality by incorporating real-time monitoring tools that check for discrepancies in production, whether it’s defects in products or irregularities in production standards. This automated inspection process ensures that only high-quality goods are produced, reducing the need for rework or returns, and maintaining a strong brand reputation.

Flexibility and Scalability

As industries evolve, production needs change. Jiko’s flexible and scalable platform allows businesses to adapt to shifting requirements. Whether you’re scaling up production for a new product launch or adjusting workflows to accommodate a shift in demand, Jiko can easily integrate new processes and expand to meet growing business needs without sacrificing efficiency or productivity.

Seamless Integration with Existing Systems

Many manufacturers are hesitant to adopt new technology due to concerns about compatibility with their existing infrastructure. Jiko solves this problem with its seamless integration capabilities. Whether you’re using legacy systems or newer platforms, Jiko connects effortlessly to your production tools, enterprise resource planning (ERP) systems, and supply chain management tools. This integration ensures that all parts of your business work together cohesively, streamlining operations and enhancing overall efficiency.

Predictive Maintenance to Reduce Downtime

Unscheduled downtime can be a major roadblock in production, leading to costly delays. Jiko employs predictive maintenance technologies to monitor equipment health in real-time. By analyzing data on machine performance, Jiko can predict when equipment is likely to fail, enabling proactive maintenance. This reduces the frequency of unplanned downtime, keeps your production lines running smoothly, and prevents costly repairs.

Sustainability Through Waste Reduction

Sustainability is more than just a trend—it’s a vital aspect of modern production. Jiko contributes to sustainability by minimizing waste across the production process. From optimizing material usage to reducing energy consumption, Jiko’s efficiency-enhancing features help companies reduce their environmental footprint while simultaneously cutting costs. This commitment to sustainability not only boosts your bottom line but also enhances your brand’s reputation as an environmentally conscious company.

Conclusion

Incorporating Jiko into your production process can lead to transformative results. From automation and data-driven decision-making to enhanced quality control and predictive maintenance, Jiko provides the tools necessary to boost efficiency, reduce costs, and increase overall productivity. As businesses continue to face growing demand for faster, more efficient production, Jiko offers a solution that not only meets but exceeds these expectations. Embracing this innovative technology is a step toward achieving long-term success in a competitive manufacturing landscape.

FAQs

What is Jiko and how does it work?

Jiko is an advanced production optimization platform that integrates automation, real-time data analytics, resource management, predictive maintenance, and quality control features into your production processes. It works by streamlining workflows, improving decision-making, and reducing inefficiencies in manufacturing operations.

How does Jiko improve production efficiency?

Jiko improves efficiency by automating repetitive tasks, optimizing resource allocation, and providing real-time data for better decision-making. It reduces downtime through predictive maintenance, minimizes waste, and enhances product quality, ensuring faster and more reliable production.

Can Jiko integrate with my existing systems?

Yes, Jiko is designed to seamlessly integrate with existing enterprise systems such as ERP, CRM, and supply chain management tools. It can be easily incorporated into your current infrastructure without causing disruptions, ensuring smooth transitions and minimizing implementation time.

Is Jiko scalable for growing businesses?

Absolutely. Jiko’s flexible platform is scalable, allowing businesses to adjust workflows and expand operations as they grow. Whether you’re launching new products or adjusting to market demand, Jiko can adapt to your changing needs without compromising on performance.

How does Jiko contribute to sustainability?

Jiko helps businesses reduce their environmental impact by minimizing waste and optimizing resource usage. With features like energy consumption tracking and material optimization, Jiko ensures that production processes are both cost-effective and environmentally friendly.