In the modern world of chemical processing, precision and reliability are everything. Industries rely on machinery that can handle tough, corrosive, and viscous fluids with ease. Among the various pumping systems used across plants and refineries, rotary gear pumps stand out as a dependable choice for smooth and efficient liquid transfer. Behind these robust pumps are professional rotary gear pump manufacturers who combine engineering excellence with advanced technology to deliver performance that industries can count on.

What is a Rotary Gear Pump?

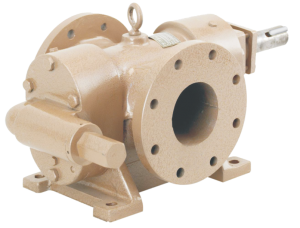

A rotary gear pump is a type of positive displacement pump that moves fluid using the rotation of gears. It is designed to handle a wide range of liquids—from thin solvents to thick oils and viscous chemicals. Unlike centrifugal pumps, which rely on velocity, rotary gear pumps deliver a constant, steady flow regardless of pressure variations.

These pumps consist of two gears that rotate in opposite directions. As the gears turn, they trap liquid between their teeth and the pump casing, carrying it from the inlet side to the outlet. This simple yet powerful mechanism makes them highly reliable and efficient, even under demanding conditions. Leading Rotary Gear Pump Manufacturers ensure precision engineering for consistent performance.

Because of their consistent flow and precise control, rotary gear pumps are especially popular in chemical processing industries where accurate dosing and safe fluid transfer are essential. Trusted Rotary Gear Pump Manufacturers design these pumps to handle challenging fluids safely. Industries seeking durable solutions often turn to professional Rotary Gear Pump Manufacturers for high-quality pumps that meet rigorous operational standards.

Why Rotary Gear Pumps Are Ideal for Chemical Processing

Chemical industries require pumps that can handle challenging fluids safely—whether it’s corrosive acids, thick polymers, or sensitive compounds. Rotary Gear Pump Manufacturers design pumps that meet these demands perfectly due to their advanced design and material options.

Here are the key reasons why these pumps are widely preferred in chemical operations:

-

Smooth and Consistent Flow

Rotary gear pumps maintain a uniform flow rate, which is crucial for chemical dosing and blending. This ensures stable operation in continuous production processes. -

High Pressure and Low Pulsation

These pumps can generate steady pressure without creating strong vibrations or pulsations, protecting sensitive chemical structures during transfer. -

Compact and Durable Design

Rotary gear pumps are known for their robust construction and space-saving design. They can operate reliably in demanding environments for long periods with minimal maintenance. -

Self-Priming Capability

A major advantage is their ability to self-prime, which means they can start pumping without needing to fill the lines beforehand. This is particularly useful in large plants handling viscous or sticky fluids. -

Material Versatility

Depending on the chemical being handled, manufacturers can build these pumps using stainless steel, cast iron, or special alloys to resist corrosion and wear.

Role of Professional Rotary Gear Pump Manufacturers

Behind every high-performing rotary gear pump is a team of skilled engineers and designers who understand both mechanical precision and industrial chemistry. Professional Rotary Gear Pump Manufacturers don’t just produce pumps—they craft customized solutions that fit the specific needs of each industry.

Here’s how they make a difference:

-

Custom Engineering

Manufacturers design pumps tailored to the type of chemical, temperature, and viscosity involved in the process. -

Advanced Manufacturing Techniques

Using CNC machining, precision casting, and modern assembly processes ensures every component meets strict tolerances. -

Quality Testing

Each pump undergoes performance, pressure, and leakage testing to guarantee safe and smooth operation under real-world conditions. -

After-Sales Support

Reliable manufacturers offer installation assistance, maintenance training, and spare parts to keep pumps running efficiently for years.

Applications of Rotary Gear Pumps in the Chemical Industry

Rotary gear pumps, supplied by trusted Rotary Gear Pump Manufacturers, are used in a wide range of chemical applications thanks to their ability to handle liquids of varying properties.

Some common uses include:

-

Acid and Alkali Transfer – For safe movement of corrosive fluids in controlled systems.

-

Solvent Handling – Ideal for transferring volatile organic solvents with minimal leakage.

-

Polymer and Resin Processing – Perfect for handling viscous and sticky materials.

-

Lubrication and Oil Circulation – Ensures consistent lubrication in process equipment.

-

Adhesive and Paint Manufacturing – Provides smooth flow of thick, high-viscosity materials.

These diverse applications highlight the versatility of rotary gear pumps across industrial setups.

Features of an Efficient Rotary Gear Pump

The best rotary gear pumps are not only efficient but also long-lasting. Here are some key features that make them stand out:

-

High Suction Efficiency – They can handle viscous liquids effortlessly.

-

Low Noise Operation – Designed for quiet performance even at high speeds.

-

Ease of Maintenance – Simple design allows for quick cleaning and part replacement.

-

Energy Efficiency – Optimized internal design reduces energy consumption.

-

Leak-Free Operation – Sealed systems prevent fluid loss and contamination.

These features make rotary gear pumps a smart choice for any chemical plant seeking reliability and operational savings.

Selecting the Right Rotary Gear Pump Manufacturer

Choosing the right manufacturer is as important as selecting the pump itself. A trusted manufacturer ensures not only product quality but also technical support, customization, and long-term value.

When selecting a rotary gear pump manufacturer, consider:

-

Experience and Reputation – Look for companies with a proven track record in pump manufacturing.

-

Material Quality – Ensure the manufacturer uses corrosion-resistant materials suitable for chemical handling.

-

Engineering Expertise – Manufacturers should provide design consultation based on your specific needs.

-

Testing and Certification – Pumps should comply with international standards for safety and performance.

-

After-Sales Service – A good manufacturer offers technical support and easy access to spare parts.

Reliable brands like JEE PUMPS exemplify these qualities, offering customized pump solutions that meet the unique challenges of chemical industries.

How Rotary Gear Pumps Improve Industrial Efficiency

Efficiency is one of the top priorities for chemical industries, and rotary gear pumps contribute significantly to it.

-

Reduced Energy Costs – Their positive displacement mechanism uses energy effectively, minimizing power wastage.

-

Lower Downtime – Durable materials and precise assembly mean fewer breakdowns and longer service intervals.

-

Improved Product Quality – Consistent flow ensures uniform chemical processing without interruptions.

-

Enhanced Safety – Leak-proof designs reduce the risk of hazardous spills.

By investing in a high-quality pump from experienced Rotary Gear Pump Manufacturers, industries gain not just a machine—but a dependable partner in long-term productivity.

Sustainability and Innovation in Pump Manufacturing

Modern Rotary Gear Pump Manufacturers are also focusing on sustainability. From energy-efficient motor designs to recyclable materials, innovation is at the heart of modern pump production.

The integration of smart monitoring systems by leading Rotary Gear Pump Manufacturers allows operators to track pump performance in real time. This reduces maintenance costs and prevents unexpected shutdowns. Additionally, environmentally friendly coatings and materials help reduce waste and extend pump life.

With continuous research and innovation, Rotary Gear Pump Manufacturers are shaping a future that offers better performance, longer durability, and lower environmental impact.

Maintenance Tips for Longer Pump Life

Proper maintenance is key to maximizing pump lifespan. Here are a few simple practices:

-

Regularly check oil levels and replace when necessary.

-

Inspect seals and gaskets for signs of wear or leakage.

-

Keep the pump clean and free from debris buildup.

-

Monitor vibration and noise levels for early detection of issues.

-

Schedule periodic maintenance from certified technicians.

With the right care, rotary gear pumps can run efficiently for years, offering unmatched reliability.

Conclusion: The Smart Choice for Modern Industries

Rotary gear pumps play a vital role in today’s industrial world. Their ability to handle diverse and demanding fluids with precision makes them an essential tool for chemical processing plants. When sourced from professional Rotary Gear Pump Manufacturers, these pumps provide the reliability, efficiency, and durability every industry needs to stay competitive.

Companies like JEE PUMPS have demonstrated how quality engineering and innovation can turn a simple machine into a powerful industrial asset. By choosing the right pump and manufacturer, industries ensure safe, smooth, and sustainable operations for years to come.

Looking to enhance your industrial operations with a high-performance rotary gear pump? Partner with trusted Rotary Gear Pump Manufacturers who understand your needs and deliver precision-engineered solutions. Choose efficiency, reliability, and innovation — invest in the best today!

Source URL : https://easybacklinkseo.com/professional-rotary-gear-pump-manufacturers-for-chemical-processing/