Industrial valves are essential components used in various industries to control the flow of liquids, gases, and slurries. These mechanical devices regulate the direction, flow rate, pressure, and volume of fluids within a piping system. Depending on their design and application, valves can stop, start, or throttle the flow to maintain a safe and efficient operation of industrial processes.

Industrial valves come in many types, such as ball valves, gate valves, butterfly valves, globe valves, and check valves. Each type serves a specific purpose, from providing a complete shut-off to offering precise control over fluid flow. In this article, we’ll explore what industrial valves are, how they work, and their applications in various sectors.

What are Industrial Valves?

An industrial valves is a mechanical device used to regulate the flow of fluids by opening, closing, or partially obstructing passageways within a pipeline. These valves are built to handle different types of fluids, including liquids, gases, steam, and even slurry. They are typically made from materials like stainless steel, carbon steel, brass, or cast iron to withstand extreme pressures, temperatures, and corrosive environments.

Industrial valves are categorized based on their function and design. The primary categories include:

- Isolation Valves: Used to completely stop the flow of fluid.

- Control Valves: Designed to regulate fluid flow and pressure.

- Non-Return or Check Valves: Prevent the backflow of fluids.

- Safety Valves: Automatically release pressure to prevent overpressure conditions.

- Pressure Reducing Valves: Reduce the pressure of the fluid to a desired level.

Each of these categories serves a unique purpose, and selecting the right valve for an application depends on factors such as the type of fluid, operating temperature, pressure requirements, and desired flow characteristics.

Working Principle of Industrial Valves

The working principle of an industrial valve depends on its design and purpose. However, most valves operate by manipulating the position of a mechanical element such as a ball, disc, gate, or plug. This element moves to control the flow path of the fluid. Let’s explore the working principles of some common types of industrial valves:

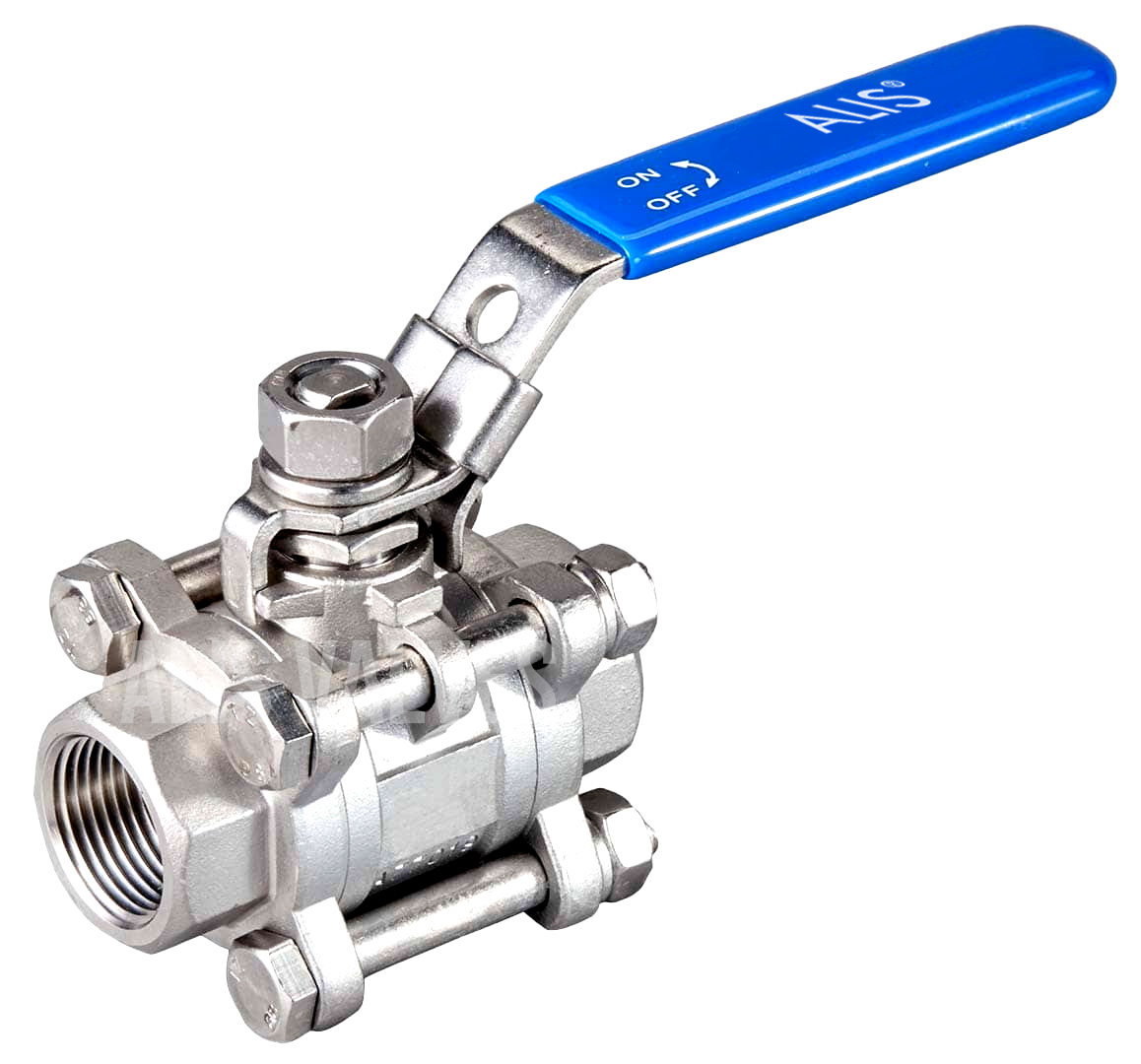

- Ball Valves: Ball valves use a spherical disc, known as a ball, to control flow. The ball has a hole through its center, which aligns with the flow path when the valve is open, allowing fluid to pass through. When the valve handle is turned 90 degrees, the ball rotates, blocking the flow. Ball valves provide quick shut-off capabilities and are commonly used in applications that require tight sealing and minimal leakage.

- Gate Valves: Gate valves operate by raising or lowering a flat or wedge-shaped gate to start or stop fluid flow. When the gate is lifted, the valve is fully open, allowing fluid to flow freely. Lowering the gate closes the valve, completely blocking the flow. Gate valves are used in applications where a full flow or no flow is required, such as in water treatment and oil pipelines.

- Butterfly Valves: Butterfly valves have a disc that rotates around a central axis within the valve body. The disc moves perpendicular to the flow direction, and when it is parallel to the flow, the valve is open. Rotating the disc 90 degrees closes the valve. Butterfly valves are lightweight, compact, and ideal for large-diameter pipes, making them popular in HVAC systems and chemical processing.

- Globe Valves: Globe valves have a spherical body with a movable plug or disc that opens and closes against a seat. The plug moves up or down to throttle flow, providing precise flow control. Globe valves are widely used in applications that require accurate regulation, such as in steam systems and fuel handling systems.

- Check Valves: Check valves allow fluid to flow in one direction only. They have a disc or ball that moves to permit flow in one direction and blocks reverse flow. These valves are used to prevent backflow in pipelines and are commonly found in water supply and wastewater systems.

- Safety and Relief Valves: Safety valves are designed to release excess pressure from a system automatically. When the pressure inside a system exceeds a predetermined level, the safety valve opens to discharge the excess fluid, thereby preventing potential damage or explosion. These valves are crucial in applications involving boilers, pressure vessels, and other high-pressure systems.

Applications of Industrial Valves

Industrial valves are used in a wide range of industries, including oil and gas, chemical processing, power generation, water treatment, and food and beverage production. Their applications vary based on the type of valve and the specific needs of the process. Here are some key industries and how they use industrial valves:

- Oil and Gas Industry: In the oil and gas industry, industrial valves are used to control the flow of crude oil, natural gas, and refined products. Valves like ball valves, gate valves, and check valves are critical in upstream, midstream, and downstream operations. They are used in wellheads, pipelines, refineries, and storage facilities to regulate flow, isolate sections of the pipeline, and ensure safety.

- Chemical Processing: Chemical plants require valves that can handle aggressive chemicals, high temperatures, and corrosive environments. Butterfly valves, diaphragm valves, and globe valves are commonly used for precise flow control and to prevent cross-contamination of chemicals.

- Power Generation: In power plants, industrial valves regulate the flow of steam, water, and fuel. Globe valves are often used to control steam flow, while safety valves protect against overpressure in boilers and pressure vessels. Gate valves and butterfly valves are used in cooling water systems and turbine controls.

- Water Treatment and Distribution: Industrial valves play a key role in water treatment plants and distribution systems. Gate valves and butterfly valves control the flow of water through treatment processes, while check valves prevent backflow and contamination. Pressure-reducing valves maintain desired pressure levels in distribution networks.

- Food and Beverage Industry: In the food and beverage industry, hygiene and cleanliness are top priorities. Valves made of stainless steel or other food-grade materials are used to regulate the flow of liquids, gases, and steam in processes such as pasteurization, sterilization, and packaging. Diaphragm valves and ball valves are popular choices due to their ease of cleaning and maintenance.

- Pharmaceutical Industry: Pharmaceutical manufacturing requires valves that can handle sterile and hygienic conditions. Diaphragm valves, pinch valves, and ball valves are used to control the flow of fluids and gases in processes like mixing, filling, and filtration.

Conclusion

Industrial valves are vital components in many industries, offering precise control over the flow of fluids. With various designs like ball valves, gate valves, butterfly valves, and globe valves, they can meet the specific requirements of different applications. Understanding the working principles and selecting the right type of valve for your needs ensures efficient, safe, and reliable operation.